TMEP helps manufacturers solve persistent production challenges through targeted, fast-moving Kaizen events grounded in practical root cause analysis.

? Real Results A Tennessee-based metal fabricator used a 3-day Kaizen event to reduce rework by 32%. The team traced the issue to inconsistent part orientation during welding and implemented a simple fixture-based solution. The fix was live by the end of the week.

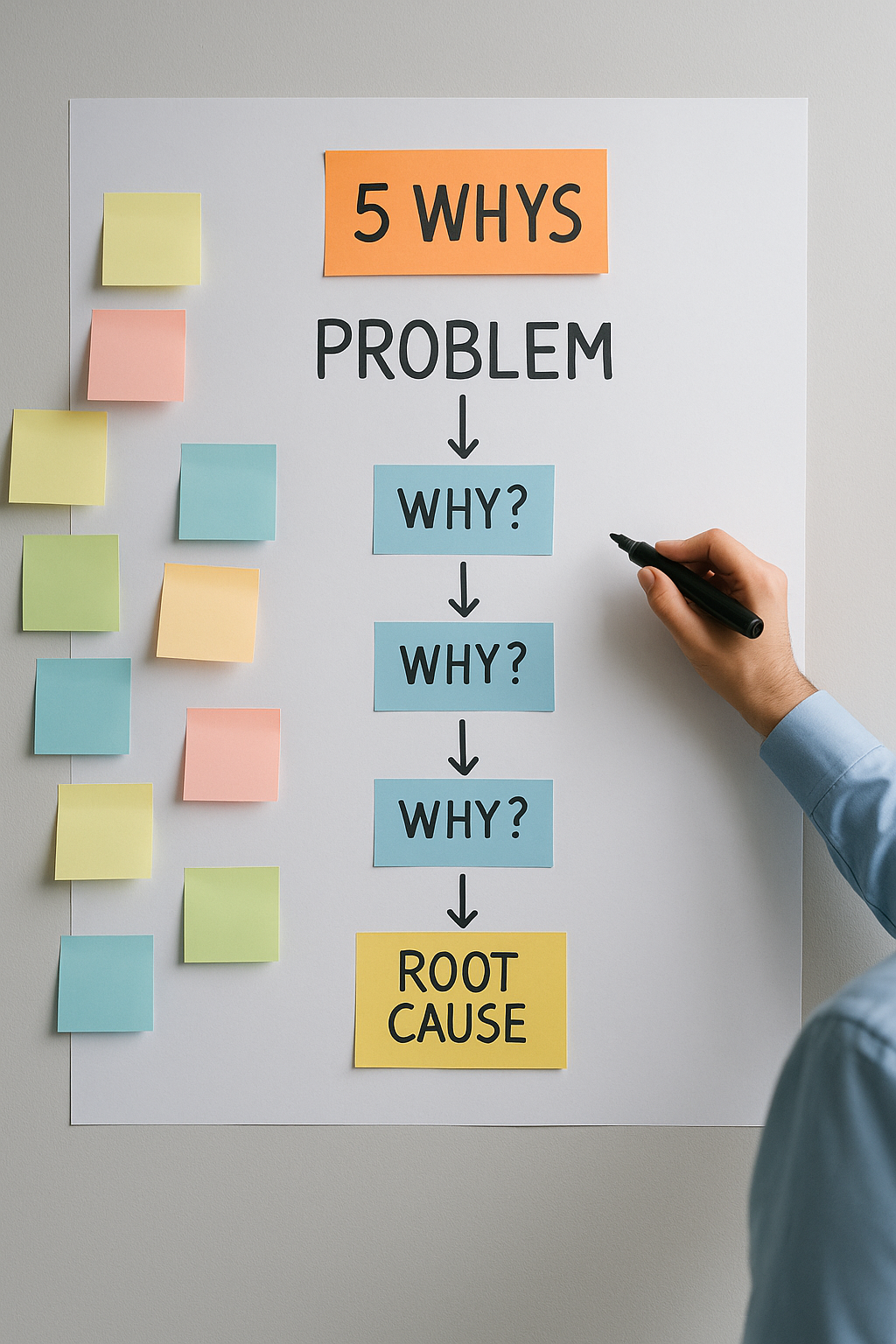

Kaizen events use practical root cause analysis tools — like the 5 Whys — to dig beneath the surface of recurring issues. This approach empowers teams to fix the cause, not just the symptom, driving lasting, measurable improvements.