| Downloads |

|---|

| TPM Overview Flyer |

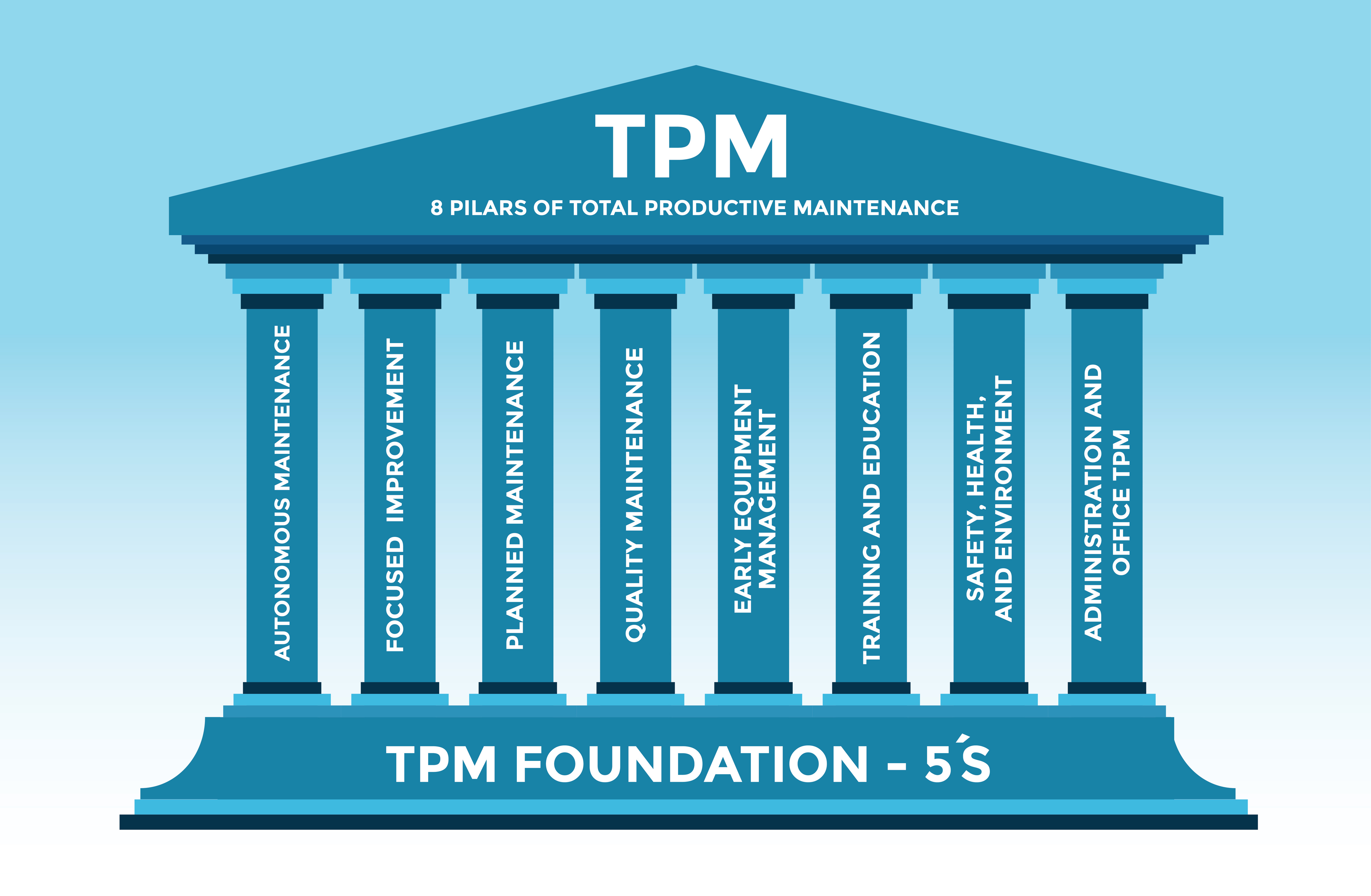

Streamline your operations with our comprehensive roadmap for Total Productive Maintenance (TPM) integration.

Is your equipment downtime killing productivity? Each minute a machine is down, you're bleeding resources, time, and opportunities. Breakdowns, unplanned stoppages, and inefficient operations can derail your business’s momentum and profitability.

In today's competitive market, the efficiency of your machinery isn't just about output; it's about maintaining an edge. TPM, or Total Productive Maintenance, is more than just a maintenance strategy; it's a cultural shift. By embracing TPM you integrate the dual powers of maintenance and production, ensuring that your machinery works for you, not against you. Partner with us to transition from reactive fixes to a proactive, productivity-driven approach and watch your business thrive.