| Downloads |

|---|

| Standardized Work Overview Flyer |

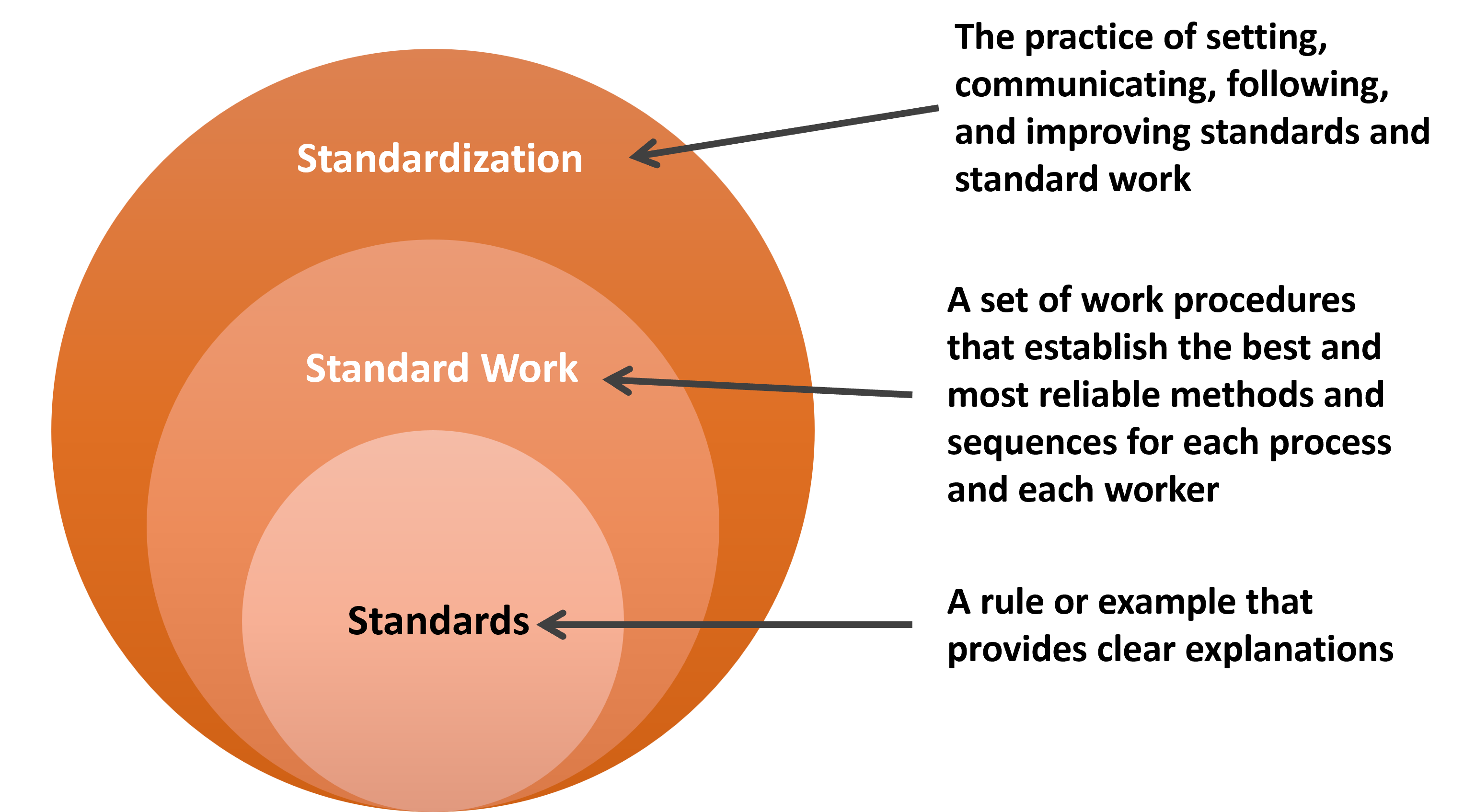

The journey to effective Standardized Work comprises:

Fluctuating quality, inefficiencies, and unpredictable outputs can hinder growth. Inconsistent processes can lead to wasted resources, miscommunication, and customer dissatisfaction, highlighting the critical need for a uniform approach.

Standardization is more than just uniformity; it's the foundation upon which high-performing companies build their success. At TMEP, we understand that every organization has its unique rhythm. Our approach to Standardized Work seeks to capture and refine this rhythm, creating a balance between structure and flexibility. By laying down clear, efficient, and tailored processes, we help you unlock a world where every task is performed with precision, every role is clearly defined, and continuous improvement becomes a daily mantra.

Standardized Work is a lean manufacturing principle that helps determine and document the precise procedures and sequence of steps involved in the process. It uses the three elements of Takt Time, Work Sequence and Standard Inventory. Standardized work helps reduce variations in the process thereby improving it.